Fun fact: there’s always moisture in wood, the question is, how much? A common myth is that water and wood don’t mix. That’s because wood actually has the ability to withstand and store water. In fact, it can do both, absorb moisture or release it, which depends on the humidity around it.

If you want to find out how moisture affects wood and how it moves, acceptable moisture levels, and how to measure them, then keep reading!

How Does Moisture Affect Wood?

Everyone who works with wood needs a solid understanding of how wood and humidity are tied together. It doesn’t matter whether you’re a woodworker, a cabinet installer or you use wood in construction, moisture content should always be top-of-mind.

Wood Can't be Stopped from Moving

Wood is hygroscopic. That means it absorbs and releases water moisture depending on the relative humidity (RH) level of its surrounding air. So, the higher the relative humidity, the higher the moisture content of the wood will become.

The varying humidity levels don’t only cause wood to gain or lose moisture but also to expand or contract. The more moisture content in wood, the more it expands. On the other hand the lower the moisture content the more wood shrinks.

How Does Wood Reach Equilibrium Moisture Content?

The wood will shrink or expand according to the environment until it reaches a “middle ground,” which is when wood neither gains nor loses moisture. At this point, wood has adapted to the humidity level of its surrounding air. When this happens, the wood has reached something called its equilibrium moisture content (EMC).

So, if a wood project has been transported or recently installed, it might take a little while for it to reach its EMC in the air. This is due to the wood being transferred from one environment to another with potentially different humidity levels.

In short, the EMC helps understand how the wood will respond to relative humidity, whether it will shrink or expand.

Here’s a calculator that you can use to find the EMC values of wood when stored at the humidity and temperatures you indicate.

Understanding How Wood Moves

It is important to understand how wood moves with the presence of humidity, or lack thereof. If the wood’s moisture content is too low (humidity decreases), the wood will shrink at such a level that you run the risk of big gaps and cracks in the wood itself. When the moisture content is too high (humidity increases), the wood will expand, buckle, bow, and distort the material around it.

There are six main areas to be aware of regarding wood movement.

1. The Width of Material

The wider the board, the more movement in direct proportion. So, a 6-in. board will move double the amount as a 3-in. board, and a 9-in. board will move 3 times as much as a 3-in. board.

NOTE: A glued panel (like a slab-style kitchen cabinet door) behaves as if it’s one wide piece of lumber. When gluing boards together to make a bigger piece, alternate the grain. See the image below for reference.

Solid wood panel component orientation from woodadvocate.com

2. The Grain Orientation Matters

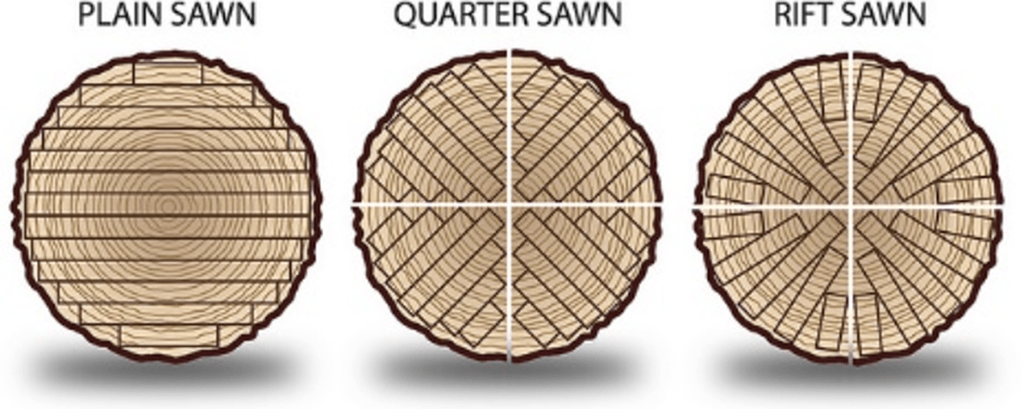

Boards are cut in a few different ways, and we’re only going to address 2 of them; plain-sawn and quarter-sawn.

Quarter-sawn lumber shrinks and expands about half as much as plain-sawn. Most finish material you can get over the counter is plain-sawn, so assume plain-sawn values unless you know your material is quarter-sawn.

The image below was pulled from a blog by Shafer Hardwood Flooring Co. which compares the 3 different cuts visually.

Source: Shafer Hardwood Flooring Co. blog post

3. Recording Wood Moisture Levels When it's Delivered

When a wood delivery arrives, the first step is to measure its moisture content with a moisture meter. Missing this vital step means zero chance of anticipating any potential movement problems.

Decor takes extra care not to miss this step, checking every pack of wood delivered for moisture content and board feet before putting any material to use for our kitchens.

4. Humidity Levels in Homes

Most North American homes lack humidity control and typically have a relative humidity level of 25% to 65%. This humidity range will cause a 6% change in the moisture content of the wood which is the equivalent of a 12-inch-wide maple board changing 1/4 inch.

NOTE: Panel materials like plywood, MDF, and melamine (TFL) move about 1/10th as much as solid wood.

5. Wood Species Affect the Amount of Movement

Part of the movement in wood depends on the species. A 12-inch-wide red alder board will shrink or expand by 1/8 in. While the same size willow oak board will change by 1/4 in.

If you want to calculate exactly how much your material is going to change, enter the high and low moisture content values and the width and species of the board into this online shrinkage calculator.

6. Even Applied Finishes Can't Stop the Movement of Wood

Finishes applied to wood won’t stop it from expanding or contracting. It’s true that finished material will swell or shrink slower than raw wood, but eventually, it will reach its equilibrium moisture content (EMC) levels.

What are Acceptable Moisture Content Levels?

Preferably, when the wood is put to use, the moisture content shouldn’t change any more than 2%.

The ideal readings for unheated areas (exterior wood) are 12-14%, assuming the area is weather-protected. For interior heated areas, the optimal moisture content level ranges between 6-8%.

For every 4% change in moisture content, wood moves 1%

Consider the average relative humidity level of the environment where the wood will be used and the wood’s final use. This will give you a better idea of what moisture level is acceptable for your situation.

Now, to find out what the moisture content level is, you’ll need a wood moisture meter.

How to Measure Wood Moisture Content?

There are two ways to measure the moisture content of wood. One is oven-dry testing and the other is simply using a moisture meter. Let’s take a quick look at each.

Oven Dry Testing

The oven-dry method (also known as kiln drying) is the oldest method out there and is time-consuming but accurate.

NOTE: Oven dry testing involves using a sample of wood which will render the sample unusable afterwards.

The wood sample is dried in an oven or kiln specially made for this purpose, and the weight of the wood sample is checked at regular intervals over time. When the weight of the wood sample doesn’t change anymore, the weight is compared to what it was before the drying process began. The difference in weight is used to calculate the original moisture content of the wood sample.

Three reasons why people have shied away from this method are:

- It takes a long time because if you go too hot to speed up the process, the wood could start to burn, rendering the test results worthless.

- The wood sample becomes useless because it becomes far too dry.

- You need a special oven or kiln, which most people don’t have.

That being said, let’s look at the alternative method.

Moisture Meter Testing

Testing the moisture content of wood using an accurate moisture meter is the fastest way to measure the moisture content of wood. There are two major types of meters. One is with pins and the other without.

Moisture Meters with Pins

Pin-type meters measure the wood’s moisture content by using electrical resistance through penetrating electrodes.

How dry the wood is can be determined by the amount of resistance to an electrical current, due to water being a great conductor of electricity – as for wood, the opposite. The dryer the wood the more resistance.

Moisture Meters Without Pins

Pinless meters use an electromagnetic sensor that scans the wood for moisture content, which doesn’t penetrate the wood and doesn’t leave any marks. Pinless meters scan the surface of the wood and cover a larger area than meters with pins, providing a more detailed picture of the wood’s moisture content.

Because pinless meters don’t damage the wood, they are the preferred measuring tool for the moisture content of expensive materials like hardwood kitchen material or hardwood floors.

If you find yourself in need of a testing meter, you can check out your local hardware store. Home Depot also has a decent one, or you can have a look on Amazon.

One of the moisture meters that Homedepot.com offers.

Bottom Line

Most people working with wood know that the humidity changes depending on the season, which can cause trim, flooring, and even cabinets to shrink in the wintertime and expand during the summer.

In fact: this movement can be accurately predicted and anticipated before installation.

All you need is a testing meter for wood and an understanding of wood movement to avoid most wood movement problems, which include warping, cracking, buckling, diminished wood strength, corrosion of fasteners, and even fungal growth.